Our Air Valve is Changing the Game.

Does down-time have your customer crying foul? Don’t let a stalled pump sideline their operations!

An FTI Air air-operated double diaphragm pump with our no-stall air valve is certain to keep your customer in the game.

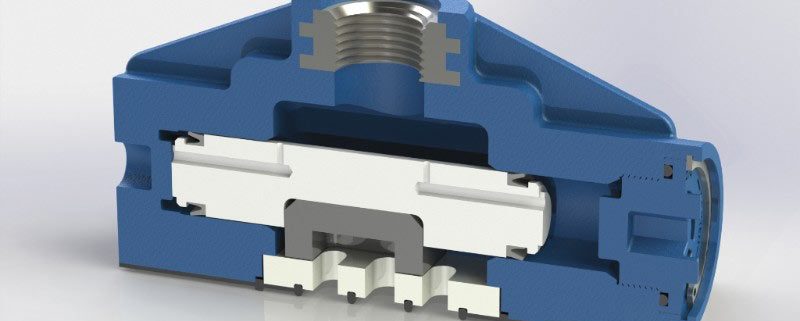

The glass-fiber reinforced polypropylene (GFRPP) or painted die-cast aluminum housing contains only three components, giving your customer a simple, leak-proof valve that prevents stalling.

Features include:

- Painted die cast aluminum or glass fiber reinforced polypropylene plastic valve body options for standard or corrosive atmospheres.

- Low friction carbon filled PTFE slide valve on the polished alumina ceramic valve plate allows for longest life and superior sealing eliminating air leakage. It also eliminates high cost seals moving over holes, as needed on many competitors’ valves.

- Molded Buna gasket fitted to grooves in the face of the valve body and slide valve plate to ensure total sealing and eliminate flat gasket tearing.

- Slotted shaft to shift the valve eliminating need for separate pilot valve or mechanically operated pilot valve. Fewer parts, simpler design and less prone to failure.

- Non-stalling design – air valve cannot stall in any position.

- Outside mounting assures easy access for inspection or maintenance – valve can be removed and serviced while pump is still installed.

- Lube free design eliminates the need for packing grease or lubricated air.

- Fewer parts reduces maintenance time and costs.

- All components are individually replaceable.

FTI Air. Change is in the Air.